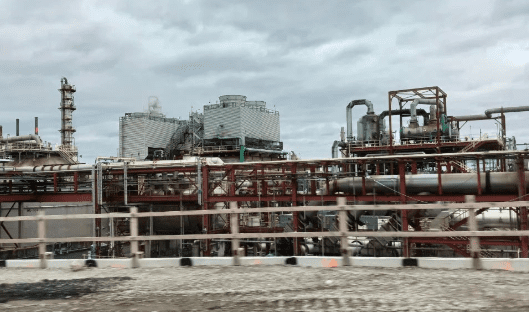

Chemical plants play a crucial role in transforming raw materials into products that power industries and sustain modern life. They are the backbone of many industries, including:

- Pharmaceuticals: Chemical plants produce raw materials for drugs and medicinal compounds that keep us healthy.

- Petrochemicals: Petrochemical plants transform crude oil into gasoline, diesel, and other fuels we rely on daily.

- Plastics: Many everyday products, from packaging to toys, come from chemical plants that process polymers into useful items.

- Agriculture: Fertilizers, pesticides, and herbicides are created in chemical plants to enhance food production and support farming activities.

- Textiles: Synthetic fibers like polyester and nylon are produced through complex chemical processes in plants.

Essentially, chemical plants are vital in transforming basic materials into the products that power industries and sustain modern life. Without them, many of the goods we use every day would not exist.

How Do Chemical Plants Do Efficient Reactions?

To ensure efficiency, chemical plants focus on several key factors. These include optimizing reaction conditions, energy management, and the use of catalysts.

Optimization of Reactions

Chemical plants aim to maximize the yield of desired products while minimizing waste. They achieve this by fine-tuning parameters such as:

- Temperature: Controlling the temperature of the reaction can significantly impact the rate and yield of the process.

- Pressure: Adjusting the pressure can influence the equilibrium of the reaction, favoring the formation of desired products.

- Reaction Time: Optimizing the time required for the reaction to complete ensures maximum efficiency and minimizes unnecessary energy consumption.

By carefully controlling these variables, chemical plants can get the most out of the raw materials they use.

Catalysts

Catalysts are substances that speed up reactions without being consumed in the process. Their use in chemical plants is widespread, offering several advantages:

- Increased Reaction Rate: Catalysts lower the activation energy required for a reaction to occur, leading to faster reaction times.

- Reduced Energy Consumption: By speeding up reactions, catalysts lower the overall energy requirement, making processes more efficient and cost-effective.

- Enhanced Selectivity: Catalysts can promote the formation of specific products, minimizing the production of undesired by-products.

The widespread use of catalysts in chemical plants is a testament to their importance in improving reaction efficiency and sustainability.

Energy Management

Chemical plants often integrate heat recycling into their processes. This involves capturing and utilizing heat generated in one process to fuel another, a practice known as **heat integration**. This approach offers several benefits:

- Reduced Energy Waste: Heat integration minimizes energy loss, leading to significant energy savings.

- Improved Overall Efficiency: By utilizing waste heat, plants can reduce their reliance on external energy sources, improving their overall efficiency.

- Lower Operating Costs: Reduced energy consumption translates to lower operating costs for the plant.

Continuous Processes

Many chemical plants operate non-stop to maintain a steady production flow. This approach offers several advantages:

- Reduced Downtime: Continuous operation minimizes downtime, ensuring a consistent flow of products.

- Higher Overall Productivity: Continuous processes lead to higher overall productivity, as there is no interruption in production.

- Improved Efficiency: Maintaining a constant production flow allows for better optimization and control of the process, further enhancing efficiency.

By considering these factors, chemical plants can carry out highly efficient reactions, ensuring that resources are used effectively, and costs remain manageable.

Are Chemical Plants Dangerous?

The answer to this question is more complex than a simple yes or no. While chemical plants handle hazardous materials, stringent safety protocols and regulations significantly reduce these dangers.

Common Risks and Their Management

- Chemical Leaks and Spills: If toxic chemicals are not properly contained, they can leak into the environment. To prevent this, chemical plants are equipped with advanced containment systems to handle any potential hazards. These systems include:

- Dikes and Bunds: These structures surround storage tanks and process units, containing spills and preventing them from reaching the surrounding environment.

- Emergency Shutdowns: Plants have emergency shutdown systems that automatically halt operations in case of a leak or spill, minimizing the impact.

- Leak Detection Systems: Advanced sensors monitor for leaks and trigger alarms to alert personnel, enabling prompt action.

- Explosions and Fires: Many chemicals are flammable or explosive. Chemical plants mitigate these risks by using special safety measures such as:

- Fireproof Materials: Plants use fireproof materials in construction and equipment, limiting the spread of flames.

- Explosion-Resistant Equipment: Equipment is designed to withstand explosions, minimizing the risk of catastrophic events.

- Fire Suppression Systems: Plants have fire suppression systems that automatically release extinguishing agents in case of fire, preventing its spread.

- Air and Water Pollution: Chemical plants are required to manage their emissions and waste carefully. Even with strict regulations, improper waste management or accidents can lead to environmental harm. To address this, plants often invest in pollution control technologies, such as:

- Scrubbers: Scrubbers remove pollutants from exhaust gases, preventing their release into the atmosphere.

- Wastewater Treatment Plants: Plants have dedicated wastewater treatment facilities to remove pollutants before discharge into rivers or oceans.

- Waste Minimization Programs: Plants implement waste minimization programs to reduce the amount of hazardous waste generated in the first place.

- Worker Health and Safety: Workers in chemical plants are regularly exposed to hazardous materials. To protect them, companies provide personal protective equipment (PPE) and rigorous training on handling dangerous substances. These measures include:

- Respiratory Protection: Workers are provided with respirators to protect them from inhaling harmful fumes.

- Protective Clothing: Workers wear specialized clothing to prevent contact with hazardous materials.

- Safety Training: Workers receive regular safety training on handling hazardous materials, emergency procedures, and proper use of PPE.

While the dangers are real, chemical plants invest heavily in safety to minimize accidents and protect workers, nearby communities, and the environment.

Chemical Plant Process: A Step-by-Step Guide

The chemical plant process involves several carefully controlled stages, each designed to ensure that raw materials are transformed into valuable products as efficiently and safely as possible.

1. Raw Material Handling

The process starts with receiving and storing raw materials. These materials can come in various forms—gases, liquids, or solids—and require specific handling methods. For example:

- Gases: Gases are stored in specialized tanks under controlled pressure and temperature.

- Liquids: Liquids are stored in tanks or drums, often with precautions to prevent spills or leaks.

- Solids: Solids are typically stored in silos or bins, with measures to prevent contamination or degradation.

2. Reactions

Chemical reactions occur inside large reactors. These reactors maintain controlled conditions such as temperature and pressure to facilitate efficient chemical transformations. For example:

- Batch Reactors: These reactors process materials in batches, allowing for flexibility in production runs.

- Continuous Reactors: These reactors continuously feed and process materials, leading to a steady flow of products.

3. Separation and Purification

After the reaction, the products need to be separated from by-products and impurities. Plants use techniques like:

- Distillation: This process separates components based on their boiling points, allowing for purification of the desired product.

- Filtration: This technique removes solid impurities from liquids or gases.

- Chromatography: This method separates components based on their affinity for a stationary phase, allowing for purification and analysis.

4. Recycling of By-products

Many by-products generated during reactions can be reused in other processes. This not only improves the efficiency of the plant but also reduces waste. This can involve:

- Reprocessing: Some by-products can be reprocessed into valuable products.

- Reuse: By-products can be reused in other parts of the plant, reducing the need for new materials.

- Waste Reduction: By-product recycling significantly reduces the amount of waste generated by the plant.

5. Packaging and Distribution

The final step involves packaging the products for distribution. This could include:

- Bottling: Products are bottled for consumer use.

- Canning: Products are canned for preservation and distribution.

- Bulk Containers: Products are stored in large containers for shipping to other industries or consumers.

By following these steps, chemical plants can carry out their operations smoothly and ensure that their processes are efficient, safe, and profitable.

List of Chemical Plants

Here’s a list of chemical plants that are well-known for their global operations and innovative processes:

- BASF: With plants in Europe, Asia, and the Americas, BASF is one of the world’s largest chemical companies. They produce chemicals used in various industries, including plastics and agriculture.

- ExxonMobil Chemical: Known for their large petrochemical plants, ExxonMobil produces fuels, lubricants, and plastics that fuel industries worldwide.

- Dow Chemical: Dow Chemical operates globally, producing everything from specialty chemicals to plastics used in consumer goods.

- SABIC: Headquartered in Saudi Arabia, SABIC is a major producer of chemicals, fertilizers, and metals, serving industries across the globe.

- DuPont: DuPont is a pioneer in chemical innovation, with plants producing specialty chemicals, advanced materials, and solutions for sustainable development.

These companies are just a few examples of the vast network of chemical plants worldwide that provide essential products to industries and consumers alike.

Common Challenges in Chemical Plants

Operating a chemical plant efficiently requires overcoming several challenges. Some of the most common ones include:

- Environmental Regulations: Governments enforce strict regulations to limit emissions and waste. To comply, chemical plants must invest in advanced pollution control technologies, which can be costly.

- Energy Costs: Chemical reactions require significant amounts of energy, and balancing these energy needs with operational costs is a constant challenge for plant managers.

- Supply Chain Disruptions: Chemical plants often source raw materials globally. Any disruption, such as political instability or natural disasters, can significantly affect production and costs.

- Innovation and Sustainability: As industries push for greener technologies, chemical plants must innovate to stay competitive. This includes developing processes that minimize waste and reduce reliance on non-renewable resources.

Enhancing Efficiency in Chemical Plants

To stay competitive and environmentally responsible, chemical plants continually seek ways to improve efficiency. Several strategies help them achieve this:

- Automation and Artificial Intelligence: Automating processes reduces human error and increases productivity. Additionally, artificial intelligence can help predict system failures and optimize reaction conditions.

- Sustainability Initiatives: Many chemical plants are investing in renewable energy sources to reduce their carbon footprint and contribute to global sustainability goals.

- Waste Reduction Techniques: By improving reaction yields and recycling by-products, plants reduce waste, which leads to more efficient operations.

Conclusion

The efficiency of chemical plants is crucial for their success. These plants play a vital role in industrial production, transforming raw materials into valuable products. Though they present challenges and risks, these facilities continue to innovate, improving their efficiency and minimizing their environmental impact. With the right safety measures and technological advancements, chemical plants will remain efficient and sustainable for years to come.

FAQs

What are chemical plants used for?

Chemical plants produce a wide range of chemicals and materials, from fuels to pharmaceuticals. They are essential for various industries, including pharmaceuticals, petrochemicals, agriculture, and textiles.

Are chemical plants dangerous?

While chemical plants handle hazardous materials, strict safety protocols help minimize risks. These protocols include advanced containment systems, fireproof materials, explosion-resistant equipment, pollution control technologies, and comprehensive worker safety training.

How do chemical plants increase efficiency?

Efficiency is improved through the use of catalysts, heat integration, and continuous process optimization. Catalysts speed up reactions, reducing energy consumption. Heat integration recycles waste heat, minimizing energy loss. Continuous processes minimize downtime and maximize productivity.

What are some famous chemical plants?

Companies like BASF, ExxonMobil, and DuPont operate well-known chemical plants worldwide. These companies are leaders in chemical production and innovation, providing essential products to industries and consumers.

What challenges do chemical plants face?

Chemical plants face challenges such as strict environmental regulations, high energy costs, supply chain disruptions, and the need for continuous innovation to meet sustainability goals.

How do chemical plants manage environmental impacts?

Chemical plants manage their environmental impact through various measures, including pollution control technologies, waste minimization programs, and the use of renewable energy sources. They strive to minimize emissions and waste to protect the environment.

What role do catalysts play in chemical reactions?

Catalysts are substances that speed up chemical reactions without being consumed in the process. They lower the activation energy required for a reaction to occur, leading to faster reaction times and greater efficiency.

What are some examples of heat integration in chemical plants?

Heat integration involves using waste heat from one process to fuel another. For example, the heat generated during a reaction can be used to preheat incoming raw materials, reducing the need for external energy sources.

Why are continuous processes beneficial in chemical plants?

Continuous processes allow for a steady flow of products, minimizing downtime and maximizing productivity. They also enable better optimization and control of the process, leading to greater efficiency.

What are some future trends in chemical plant technology?

Future trends in chemical plant technology include increased automation, the use of artificial intelligence, and the development of greener processes that minimize waste and reduce reliance on non-renewable resources.

If you’re interested in learning more about tech news, feel free to visit my website: www.HowToGrowPlant.com.